Figure 03 and the Future of Humanoid Robotics: From Factory to Front Door

Built for the Real World: Why Figure 03 Is a Breakthrough in Home Robotics

Figure 03 is the first humanoid robot built for real-world tasks and mass production. Discover how Figure AI is bringing robots into homes, what sets this model apart, and why it marks a turning point in robotics.

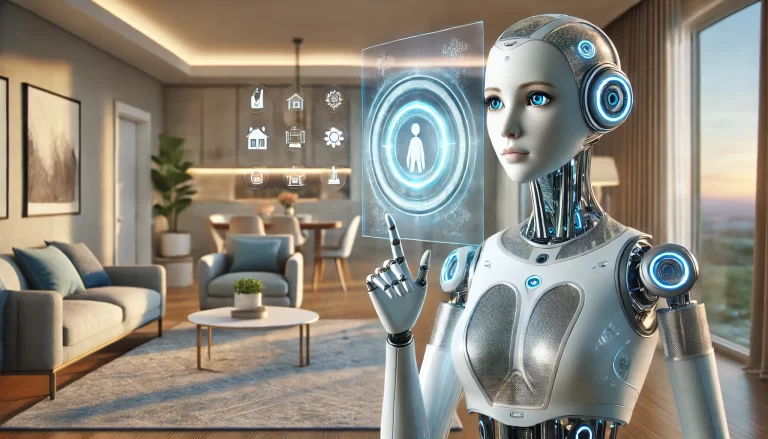

Robots that can live and work alongside humans have long been a staple of science fiction. But with the launch of Figure 03, that vision is starting to look a lot more real.

Unveiled on October 9, 2025, by California-based Figure AI, this third-generation humanoid robot isn’t just another prototype built for tech demos. It’s the company’s first model designed for mass production and real-world tasks. With advanced AI, human-like dexterity, and home-safe engineering, Figure 03 is built to handle everyday chores, including loading dishwashers and folding laundry, in actual homes and workplaces.

What makes this moment different is the scale. Backed by a purpose-built facility capable of producing up to 12,000 units a year, Figure AI is aiming to move beyond labs and into living rooms.

This article explores what makes Figure 03 a breakthrough, how it works, what it’s capable of today, and why it could signal the beginning of a new era in humanoid robotics.

1. What Is Figure 03, and Why Does It Matter?

For years, humanoid robots have fascinated the public, but most never moved beyond research labs or scripted demos. That changes with Figure 03, unveiled by Figure AI on October 9, 2025. This robot is not a proof of concept. It is designed to work in the same spaces as people and to perform real, everyday tasks.

A Robot Built for Human Spaces

Figure 03 is a full-sized humanoid equipped to operate in homes and workplaces. It walks upright, has articulated hands, and features soft, impact-friendly materials. It is designed for common chores such as carrying items, folding laundry, and unloading a dishwasher. Rather than rely on rigid, pre-programmed sequences, it adapts to changes in its environment, giving it flexibility that most robots lack.

Smarter Than the Average Bot

Powering the robot is Helix, an AI system that combines visual recognition, natural language understanding, and motion planning. Helix enables the robot to process voice commands, identify objects, and respond with context-aware actions. For example, it can distinguish between a glass cup and a plastic one, then choose the right grip strength automatically. This allows Figure 03 to handle a wide range of tasks with both care and accuracy.

Designed for Mass Production

The most important difference between Figure 03 and previous humanoid robots is its scalability. Figure AI developed this model with mass production in mind. The company built a factory, known as BotQ, with the capacity to produce up to 12,000 units per year. Every component of the robot, from its wiring to its external shell, has been engineered for efficient assembly and high-volume manufacturing.

Why It Matters

Figure 03 represents a shift in the robotics industry. It is not just capable. It is built to be used, deployed, and eventually, purchased. This may be the first humanoid robot that is truly ready to leave the lab and enter the real world.

2. Who Is Behind Figure 03? The Rise of Figure AI

The robot may be impressive, but understanding the company that built it is just as important. Figure AI is not a legacy robotics firm or a research spinoff. It’s a startup built from the ground up with a singular goal: to create general-purpose humanoid robots that can function in the real world. In just a few years, it has gone from bold idea to producing one of the most advanced robots aimed at mass-market use.

A Mission That Breaks the Mold

From the beginning, Figure AI wasn’t interested in building robots that sit in labs or perform narrow, repetitive tasks. The company was founded with the intent of solving one of the hardest problems in technology by creating a robot capable of performing a wide range of tasks across multiple environments, including homes, warehouses, and offices.

This vision required rethinking how humanoid robots are designed, trained, and deployed. Rather than chase flashy demos, Figure AI focused on engineering fundamentals and long-term viability.

A Team with Serious Credentials

Behind the company is a team of engineers, AI researchers, and robotics veterans from places like Tesla, Boston Dynamics, Google DeepMind, and Apple. Their combined expertise spans hardware design, artificial intelligence, embedded systems, and large-scale production. Exactly the mix needed to tackle a project of this scope.

This multidisciplinary foundation gives the company a unique edge: it can build both the intelligence and the physical body of the robot in-house, without relying on external platforms or vendors for core systems.

Building for the Real World

Perhaps the most important part of Figure AI’s strategy is its focus on manufacturability. Unlike many research-oriented robotics projects, Figure AI designs its robots with scalability in mind. That focus led to the development of BotQ, a dedicated production facility capable of building thousands of Figure 03 units per year.

This means Figure AI isn’t just building a robot. It’s building the infrastructure to make robots common in everyday life.

3. What Makes Figure 03 Different from Other Robots

Many companies have developed humanoid robots that can walk, wave, or lift objects. What sets Figure 03 apart is not just that it works, but that it is built to function at scale, in real homes, and with intelligence that adapts to unpredictable environments. This robot focuses on practicality, not just performance.

Designed for the Real World, Not Just the Lab

Most humanoid robots are designed for research or tightly controlled settings. Figure 03 is built for something else entirely. It is engineered to operate in unstructured spaces, where objects may be misplaced, lighting varies, and people move unpredictably.

Its frame is compact and human-sized, allowing it to move through standard doorways. Its joints enable smooth, precise motion. The soft-touch exterior helps reduce risk when working near people or handling fragile objects.

Hands That Actually Work

The hands on Figure 03 are among its most advanced features. Each is designed for fine motor control, with tactile sensors, force feedback, and precision hardware. These hands can handle a wide range of real-world items, from fragile glassware to soft laundry, without damaging them or dropping them.

Combined with its vision and AI systems, the robot can pick up, carry, place, and sort objects with surprising accuracy and consistency.

Built to Learn, Not Just Perform

Figure 03 is powered by Helix, an AI model that helps the robot perceive its surroundings, understand spoken commands, and act based on context. This allows the robot to go beyond scripted routines and handle flexible instructions.

For example, a user might say, “Clear the table.” Figure 03 can assess the scene, identify which objects don’t belong, and move them to appropriate locations. It does not need step-by-step programming to complete common tasks.

Ready to Ship, Not Just Showcase

What truly makes Figure 03 different is that it is ready for manufacturing. Figure AI has built the robot using modular parts and scalable systems, making it faster and more affordable to produce.

This focus on real-world deployment — not just technical success — is what puts Figure 03 in a category of its own.

4. How Is Figure 03 Being Mass Produced?

Figure AI didn’t just build a robot that works. It built one that can be manufactured at scale. That alone separates Figure 03 from most other humanoid robots, which often remain one-off prototypes or limited-run tech demos.

The company’s commitment to production is reflected in both the robot’s design and its new manufacturing facility.

Purpose-Built for Assembly

Figure 03 was developed with scalability as a core requirement. The engineering team streamlined internal systems, simplified wiring, and used modular components. These decisions were not made to save time in development, but to make the robot easier to build, maintain, and replicate.

Materials were also chosen with production in mind. Components that would normally require custom machining were redesigned for methods like die casting or injection molding. This makes it possible to produce parts faster, more consistently, and at lower cost.

The BotQ Factory

To bring Figure 03 to life at scale, Figure AI launched BotQ, its first dedicated production facility. The factory is designed to manufacture up to 12,000 robots per year in its current form. This is a significant number for humanoid robotics, where even small batches are uncommon.

BotQ isn’t just about volume. It’s also structured for iteration. As Figure 03 evolves, the factory can adapt its processes to support hardware upgrades or design refinements.

A Step Toward Accessibility

Mass production doesn’t just mean more robots. It also means potential cost reductions, faster rollout, and broader access. By approaching robotics with a product mindset, Figure AI is trying to do what most companies have not: turn complex, intelligent machines into tools that everyday people can eventually own.

5. What Can Figure 03 Actually Do Today?

The most important difference between Figure 03 and many other humanoid robots is thThe most exciting thing about Figure 03 isn’t how it looks or how it’s built. It’s what it can already do. Unlike many robots that exist only in tightly controlled labs, this model is actively performing useful, unscripted tasks in semi-structured environments — and doing so with impressive consistency.

Real Chores, Real Autonomy

Figure 03 has been shown performing a variety of basic household and workplace tasks. These include:

- Folding laundry and placing it into storage bins

- Unloading a dishwasher, one item at a time

- Carrying objects like shopping bags or small boxes

- Cleaning surfaces, such as tables or countertops

- Interacting with humans using natural language input

These tasks are not pre-programmed routines. Instead, they are guided by the robot’s internal AI, which breaks down verbal instructions, assesses the environment, and determines the appropriate sequence of actions.

Humanlike Movement and Spatial Awareness

Figure 03 walks upright using a natural gait that allows it to move through narrow passages and around obstacles. It can pivot, kneel, and shift its weight to reach lower surfaces, making it well-suited for homes and offices.

Its balance control and motion planning are engineered to handle changes in flooring, object height, and layout, all without external rails or guides.

Hands That Adapt to the Task

Each hand on Figure 03 is equipped with multi-jointed fingers and tactile sensors, allowing it to pick up fragile or irregular objects with control and care. The robot doesn’t just follow a fixed script. It adjusts its grip based on the material, shape, and position of the item.

Still Evolving, But Already Useful

Figure 03 isn’t flawless. It works best in relatively organized spaces and within the limits of its current task library. But for a general-purpose humanoid robot operating outside the lab, its capabilities are not just impressive. They’re usable.

6. How Does It Compare to Other Humanoids?

Figure 03 isn’t the only humanoid robot making headlines, but it might be the most production-ready. To understand its position in the market, it helps to look at how it compares to other well-known projects like Tesla Optimus, Boston Dynamics’ Atlas, and a growing wave of Chinese humanoid prototypes.

Tesla Optimus: Similar Vision, Different Timeline

Tesla’s Optimus is one of the closest conceptual competitors. It also aims to be a general-purpose humanoid designed for factory work and, eventually, home use. However, while Optimus has shown promising development, it appears to be several steps behind in terms of real-world demonstrations.

Unlike Figure 03, Optimus has yet to show fluid, complete task sequences like dish unloading or laundry handling. Tesla’s prototype is still in early-stage testing, and the company has not detailed a specific production ramp like Figure AI has.

Boston Dynamics Atlas: Power Without Purpose

Atlas is famous for its agility and athleticism. It can jump, run, and perform acrobatic feats that surpass anything Figure 03 has shown. However, Atlas was built primarily for research and demonstration, not for deployment.

It lacks a pathway to consumer or industrial use, and it’s not designed for tasks like folding clothes or interacting with household objects. Figure 03 may not be as athletic, but it’s far more practical.

Chinese Robotics: Rapid but Unfocused

Several companies in China are racing to develop humanoids with impressive hardware. However, many of these models are still focused on form over function, showing impressive demos with limited context or reliability data.

Figure 03 may not be the flashiest, but it has a clear edge: a complete system, tested tasks, and a real plan to ship.

7. When Will Robots Like Figure 03 Enter Our Homes?

With the rollout of Figure 03, the question shifts from “Can we build this?” to “When will people actually live with it?” While the technology is real and production is underway, full adoption in everyday homes won’t happen overnight.

Early Use Will Be Limited and Controlled

In the next few years, Figure 03 is most likely to appear in controlled environments. Think of pilot programs in assisted living centers, high-tech smart homes, or research partnerships with universities and hospitals. These early deployments will help refine performance and gather feedback in live settings.

The goal is to prove reliability, safety, and usefulness in real life before pushing toward broader home use.

Manufacturing Is Ramping Up, But Still Small

Even though Figure AI’s BotQ factory aims to produce 12,000 units per year, that number is modest by consumer tech standards. Many of those early units will likely go to enterprise clients, strategic partners, and internal testing rather than retail consumers.

As production scales and costs drop, broader rollout will become more realistic. But that could take 3 to 5 years, depending on market demand, logistics, and regulation.

Homes Will Need to Adapt Too

For humanoid robots to work well in homes, the homes themselves may need to evolve. Robots like Figure 03 work best in organized, robot-friendly environments. Smarter layouts, accessible storage, and IoT-connected appliances could become part of the standard “robot-ready” home.

8. Why This Matters: The Bigger Picture of Domestic Robotics

The development of Figure 03 is about more than a single robot. It’s a signal that general-purpose robotics is moving closer to real-world integration, and that shift brings big questions with it. From how we work to how we live, the arrival of useful humanoids could reshape daily life in ways we’re only beginning to understand.

Rethinking Labor and Assistance

One of the most obvious impacts will be on domestic labor. If robots like Figure 03 can reliably perform chores, support caregiving, or assist elderly individuals, that could dramatically change how we manage time, care, and home responsibilities.

This kind of technology has the potential to relieve pressure on overworked caregivers, aging populations, and busy families.

Economic Shifts and Job Impacts

Widespread deployment of robots could eventually influence job markets. While home use may not disrupt traditional employment right away, broader adoption in logistics, hospitality, and elder care could reshape parts of the workforce. The key challenge will be finding a balance between automation and inclusion, ensuring that robots enhance human capability rather than replace it entirely.

Trust, Privacy, and Coexistence

With any robot that lives in your home, issues of trust and privacy come into play. Will it record data? Will it respond safely to mistakes or changes in environment? Building ethical AI systems that respect boundaries and follow clear rules will be just as important as technical performance.

9. Conclusion: A New Era, or Just Another Tech Demo?

Figure 03 may not be perfect, but it’s a major step forward. It’s not just a prototype in a lab or a flashy demo for headlines. It’s a functional humanoid robot with a clear path to manufacturing, deployment, and eventual adoption in everyday life.

With working hardware, a scalable production plan, and task-level intelligence powered by Helix, Figure 03 sets a new standard for what’s possible and what’s next.

Whether or not it becomes a household fixture in the next few years, it’s already influencing how we think about robotics, automation, and human-machine interaction. The era of general-purpose humanoid robots is no longer theoretical. It has begun. The question now is how far, how fast, and how widely it will spread.